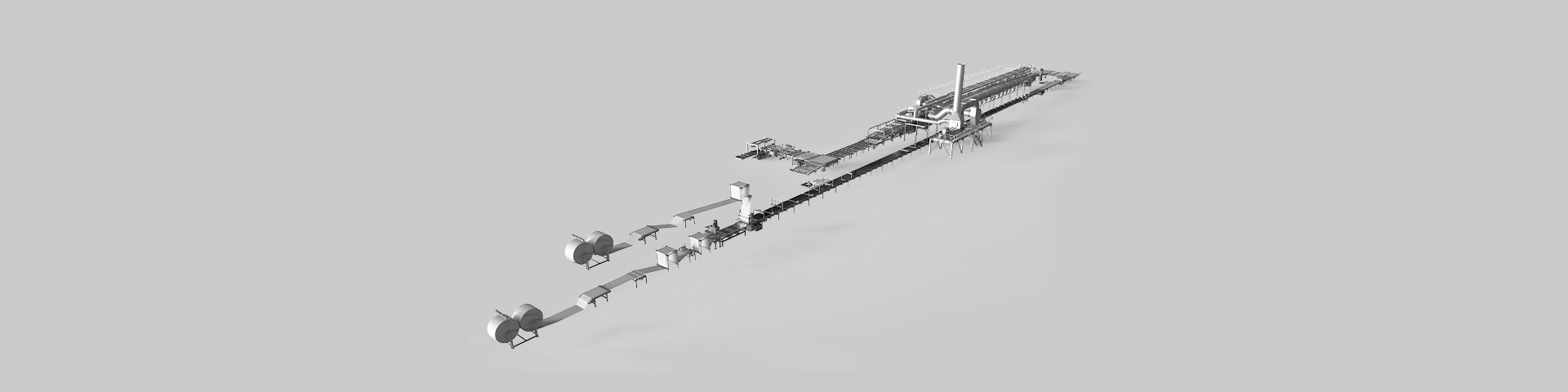

Dry materials preparing station

The Dry Materials Preparation Station is a critical section of the plasterboard production line, responsible for handling and preparing all dry raw materials—primarily gypsum plaster and a range of dry additives. As plaster is the main component of gypsum board, its proper storage, transfer, and accurate metering are essential to ensure consistency and reliability in the production process. This station includes systems for storing bulk plaster, conveying it to the mixer, and weighing it precisely before mixing.

In addition to plaster, several dry additives—such as starch, setting accelerator, and glass fiber—are also introduced into the mix based on the specific production recipe. These materials require appropriate storage conditions and dust-free transfer systems to maintain product quality and minimize losses. The dosing systems used in this station are designed to deliver each additive in accurate amounts, ensuring the final gypsum slurry meets strict quality and performance standards. Overall, the dry preparation station plays a key role in maintaining product consistency, optimizing material usage, and supporting the high-quality output of the plasterboard production line.

The Dry Materials Preparation Station is a key component of the plasterboard production line, designed to handle, store, dose, and transfer all dry raw materials with high accuracy and efficiency. This station is divided into two main functional areas: the Plaster Preparing Station and the Dry Additive Preparing Station, each equipped with specialized equipment to ensure precise material flow and preparation in line with production requirements.

1. Plaster Preparing Station

This unit is responsible for storing, conveying, and metering the gypsum plaster, which forms the core of the plasterboard. It includes:

- Plaster storage silos, designed for high-capacity bulk material storage with integrated level monitoring systems

- Plaster metering belt weighers, which ensure accurate and consistent material dosing to the production line

- Bucket elevators, used for vertical transport of plaster from ground-level systems to elevated processing points

- Screw conveyors, enabling horizontal and inclined material transfer between equipment

- Rotary valves, facilitating controlled discharge of plaster from storage or conveying systems while maintaining airlock integrity

- Slide gates, used for flow control and isolation of bulk materials during maintenance or process adjustments

2. Dry Additive Preparing Station

This section manages the handling of auxiliary dry materials such as starch, setting accelerators, and glass fibers, which are critical for board performance and processing properties. It includes:

- Additive loading crane, used for efficient and safe feeding of bulk additive materials into the system

- Additive transfer system using dense-phase conveyors, ensuring gentle and dust-minimized transport of fine powders over longer distances

- Additive storage bins, equipped with level sensors and designed to prevent material bridging or clogging

- Additive dosing systems, providing high-precision metering of each additive in accordance with the production recipe, ensuring formulation accuracy and process stability

- Transfer screw conveyors, which move dosed materials to the mixing point

- Mixing screw conveyor, responsible for homogenizing the dry additives before introduction into the wet mixing process

Dust Collection and Environmental Control

To ensure a safe, clean, and efficient working environment, the entire Dry Materials Preparation Station is integrated with a high-performance dedusting system. This system captures and filters airborne particles generated during material handling and transfer, helping to maintain a dust-free production area in compliance with occupational safety and environmental standards.