Dryer

– Engineered for Uniform, Efficient Drying

The Dryer is a critical component in the plasterboard production line, where the boards are cured to reach their final strength and stability. Dryers can be of different types: cross-section, longitudinal, hybrid and etc. The drying process must be precisely controlled to assure uniform drying of each board in it.

We offer a Cross-Section Dryer, a proven and efficient drying solution preferred for its uniform air distribution, optimized energy use, and adaptability to various capacities and board types.

Engineering Design and Functionality

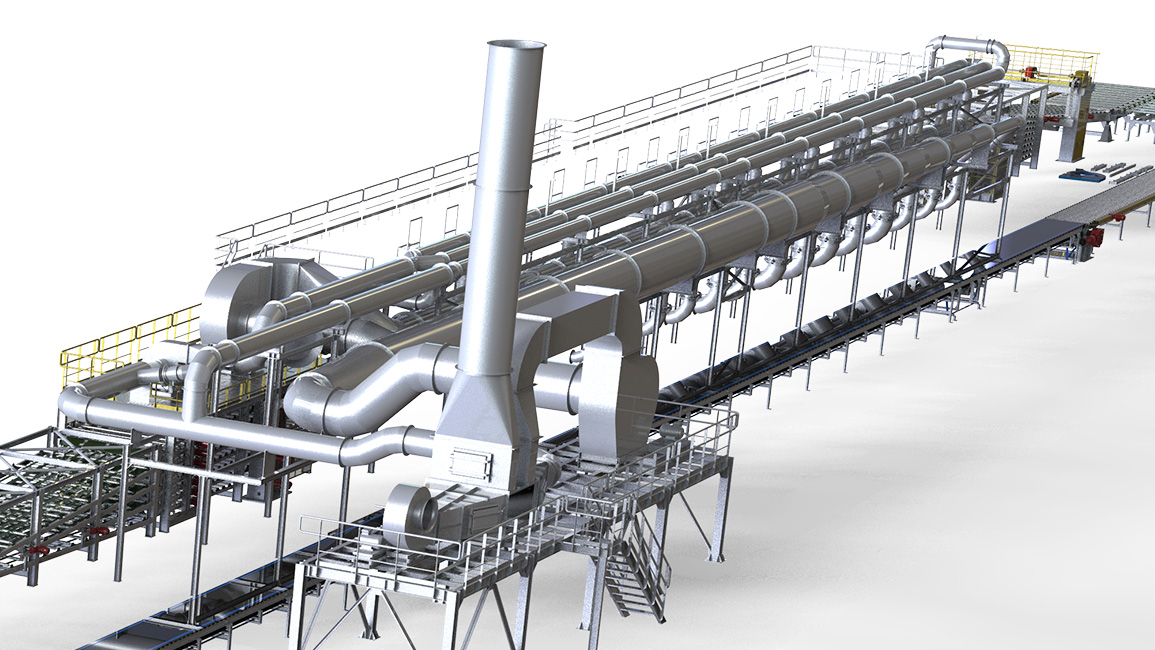

The Cross-Section Dryer is divided into multiple zones and multiple decks, the number of which depends on the production line’s capacity.

Each zone is independently equipped with:

- High-efficiency burners for controlled heat generation.

- Circulation fans to drive hot air through the board stacks.

- Hot air channelsthat ensure optimal airflow across and around the boards.

Hot air generated by burner has to be fed into hot air channels and has to be circulated efficiently in the dryer. Thus, the way hot air fed into hot air channels and the air pathway has to be designed to provide high efficiency.

The geometry and layout of these pathways are critical for:

- Uniform heat distribution across the full width and length of each board

- Consistent drying on both surfaces—eliminating problems like one side being overdried or underdried

- Improved energy efficiency by minimizing heat loss and maximizing recirculation of hot air

- Stable operation, maintaining drying quality even at maximum output

Dryer Design Matters

Unlike other types (longitudinal or hybrid), the cross-section dryer allows for shorter overall dryer length while still achieving even drying. This makes it a space-efficient and energy-conscious solution without compromising on board quality.

Performance You Can Rely On

With a strong engineering foundation and precision air control, our cross-section dryer ensures:

- Smooth, stress-free drying without warping or cracking

- Uniform board quality

- Optimal energy consumption through optimized burner and fan coordination

- Higher production reliability due to balanced thermal and mechanical performance