Setting Belt Conveyor

– Controlled Support for Core Setting

The Setting Belt Conveyor is a fundamental part of the plasterboard production line, responsible for transporting the freshly formed gypsum board as its core undergoes the initial setting process. Positioned directly after the Forming Station and before the Cutting Section, the setting belt provides a stable, continuous, and controlled path that supports the board during the critical phase of solidification.

Function and Purpose

The setting belt's primary function is to carry the endless web of plasterboard while the chemical reaction between water and gypsum (hydration) progresses, allowing the slurry to transform into a solidified core before the board is cut into individual panels.

This section must ensure:

- Uniform support to maintain board shape and thickness

- Steady and synchronized movement with the production line

- Minimized vibration and disturbance to avoid defects like cracks, uneven edges, or delamination

Proper setting on this belt directly impacts product strength, dimensional stability, and edge integrity.

Main Components

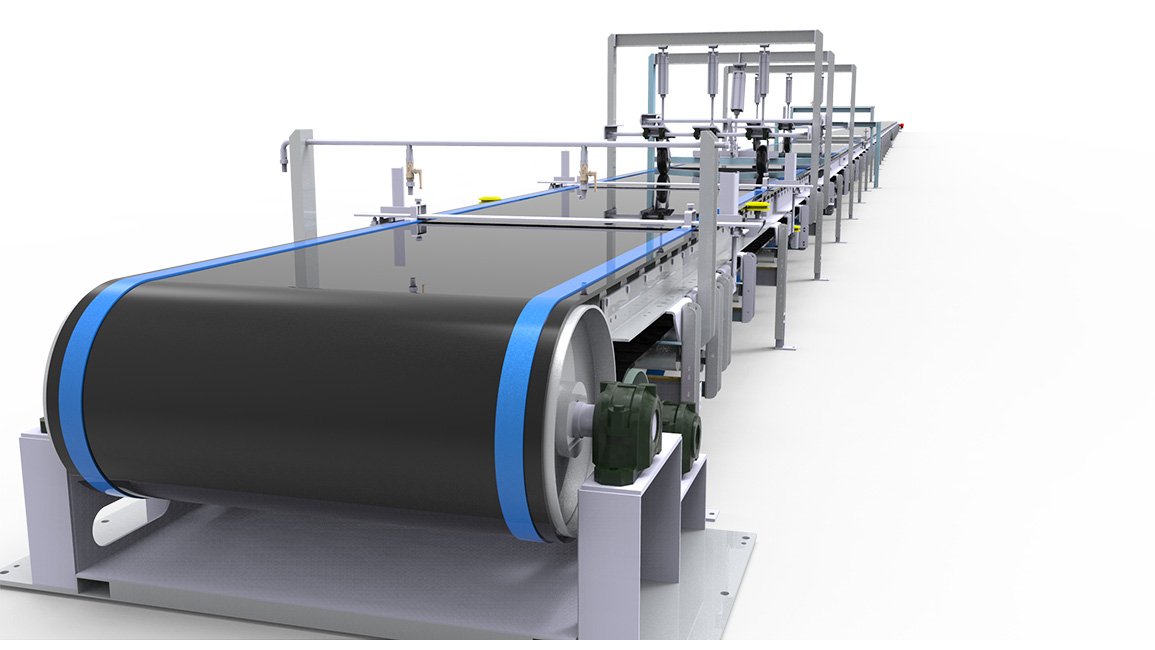

The Setting Belt Conveyor is designed for durability, precision, and low maintenance, and is typically made up of the following components:

- High-performance rubber belt: Specially developed to resist stretching (prolongation) over long-term use. This belt ensures consistent transport speed and surface stability, even under high loads and temperature variations

- Tapered edge belt: The belt features profiled/tapered edges to guide and support the folded edges of the cardboard, keeping the gypsum core centered and properly shaped

- Heavy-duty support rollers: Precisely aligned rollers support the belt and minimize resistance, ensuring smooth motion and reduced wear

- Drive system with motor-gearbox: A robust motor and gearbox assembly, controlled by the automation system, ensures synchronized and constant belt speed, matching the overall line throughput

- Tensioning and tracking system: Maintains optimal belt alignment and tension to prevent drift, slippage, or misalignment that could affect board quality

- Automation & control system: Integrated sensors and PLC-based automation monitor and adjust the belt’s motion, ensuring it remains perfectly synchronized with upstream and downstream processes

Technical Importance

For Plasterboard Quality

- Maintains board geometry during setting, preventing sagging or deformation

- Prevents early cutting or over-setting, both of which can lead to mechanical weaknesses or processing issues

- Ensures proper edge and surface finish before trimming and drying

For Production Efficiency

- Critical to line continuity – any fault here stops the entire flow

- Minimizes scrap due to board damage or misalignment during setting

- Supports high-speed operation without compromising the setting process

The Setting Belt Conveyor is much more than a transport device—it's a precision-engineered part of the line that directly influences the strength, shape, and quality of every plasterboard produced. Built for performance and reliability, it enables stable production and consistently high-quality output.