Forming Station

– Shaping the Core of Plasterboard Excellence

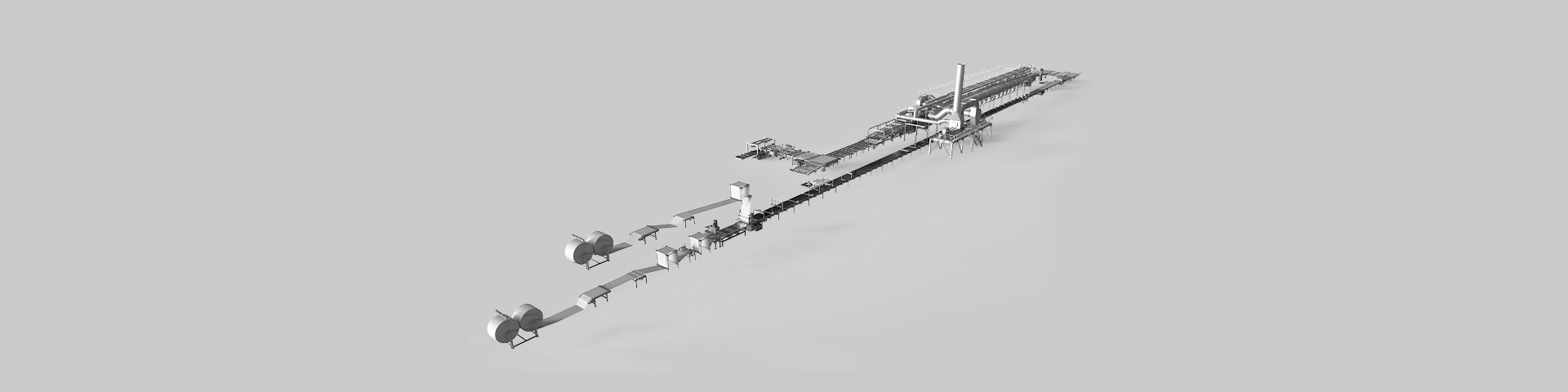

Vibrating table and form-press unit

The Forming Station in the plasterboard production line—where the gypsum slurry becomes a solid product and takes its final shape. This station is responsible for creating the continuous board web with precise dimensions, surface alignment, and edge quality that define high-performance gypsum board.

Designed exclusively for shaping the endless flow of material, the forming station combines mechanical precision and process expertise to ensure that every plasterboard produced meets the strictest quality standards.

Vibrating Table – Perfect Spread, Every Time

The first step in the forming process takes place on the vibrating table, a highly efficient platform fitted with two vibration rolls. As the slurry is poured onto the moving lower cardboard, the vibrating rolls agitate the surface, causing the slurry to spread quickly, evenly, and consistently across the width of the board.

This ensures:

- Uniform thickness distribution

- Even bonding between gypsum core and cardboard

- Elimination of air pockets and surface defects

A perfectly leveled and uniformly spread slurry at this stage is key to downstream quality and performance.

Form-Press Unit – Precision in Shape and Structure

Following the vibrating table, the material flows into the Form-Press Unit, sometimes referred to as the extruder. This sophisticated machine is where the plasterboard is truly "formed." It defines the board’s final thickness, edge profile, and cardboard folding, setting the physical characteristics of the board before it enters the setting and drying phases.

Key operations performed in the form-press:

- Board thickness control

- Edge shaping for tapered or square edges or other shapes as per customer needs

- Cardboard folding and bonding under pressure

- Ensures perfect encapsulation of gypsum core

The form-press is highly adjustable and designed for rapid changeovers, allowing for the production of various board types with minimal downtime.

Why the Forming Station Matters

The forming station is critical to product quality, consistency, and production efficiency. Even the best raw materials and perfect mixing are not enough without precise forming.

This station:

- Sets the final dimensions and visual appearance of the board

- Ensures correct edge profiles, vital for joint treatment and installation

- Controls board thickness and density, impacting mechanical strength and weight

- Allows high-speed, continuous production without sacrificing accuracy

The Advantage of Precision Forming

A high-quality forming station translates into:

- Fewer defects and rejects

- Higher production speeds

- Consistent edge and thickness quality across the board

- Enhanced downstream processing and cutting performance

At the core of every top-tier plasterboard is a perfectly functioning forming station—and that’s exactly what we deliver. Engineered with precision, powered by innovation, and designed for reliability, our forming station ensures that every board starts strong and finishes even stronger.