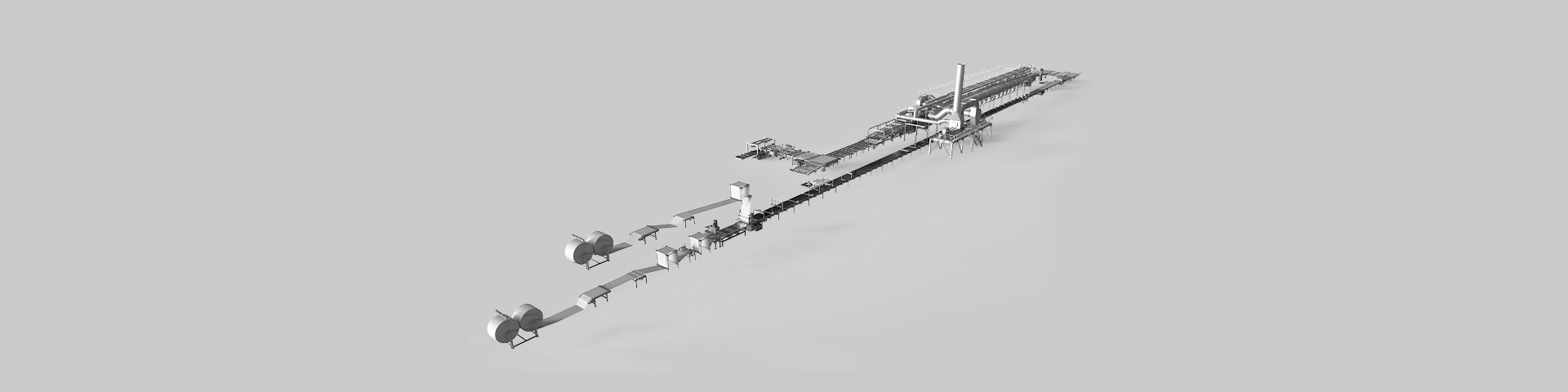

Tipple and Dryer Inlet Group

– Precision Feeding into the Dryer

The Tipple and Dryer Inlet Group ensures accurate and efficient feeding of plasterboards into the multi-deck dryer, a key step for consistent drying and performance.

The Tipple is a vertically moving feeder that lifts or lowers to align with the required dryer deck level, directing boards precisely where they need to go. Its smooth and controlled motion helps prevent board damage and supports optimal loading distribution across the dryer decks

Following the tipple, boards move onto the Dryer Inlet Group, a roller-based conveying system made of durable stainless steel rollers. This section smoothly transfers the boards into the dryer. The system includes chains, sprockets, belts, motor-gearboxes, and a counterweight structure to maintain proper tension and ensure stable operation of the drive system.

Together, the tipple and dryer inlet group provide reliable, synchronized board transfer—supporting continuous, high-quality plasterboard production.