KNIFE

– Precision Cutting for Perfect Plasterboard Lengths

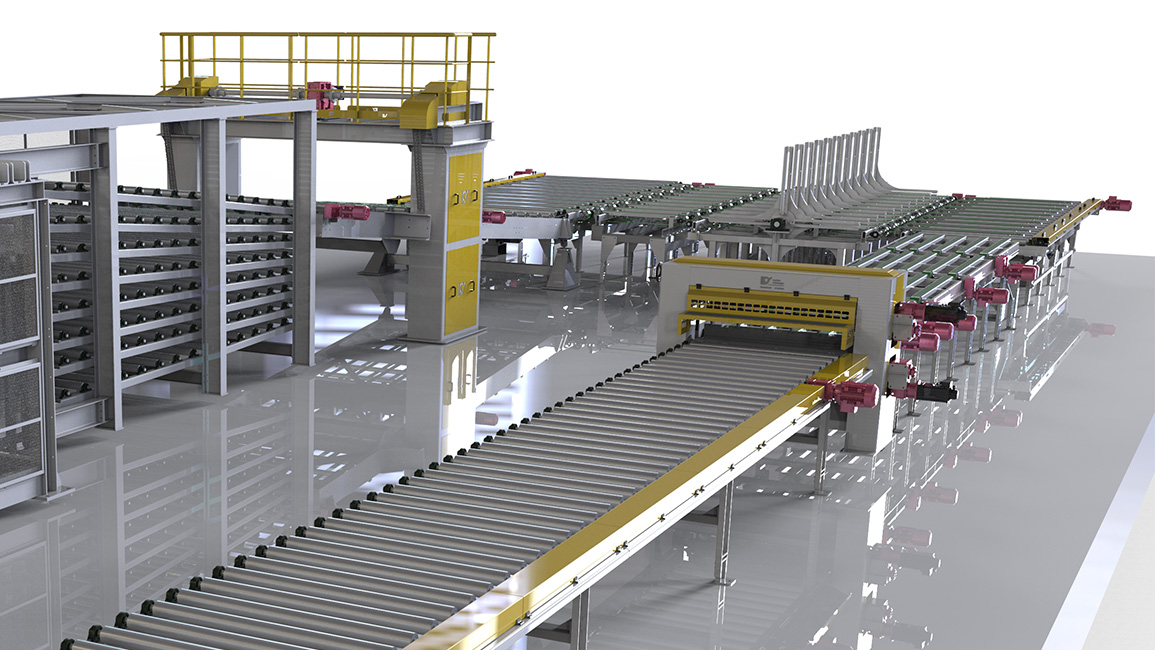

The Knife, a Lengthwise Cutting Machine, is one of the machines in the plasterboard production line responsible for cutting the endless plasterboard web into individual boards of precise length. Located after the Setting Belt Conveyor, this unit performs one of the final forming operations before the boards enter the drying process.

Function and Role in the Production Line

The main function of the knife is to cut the continuously moving board web into defined lengths according to the production requirements (e.g., 2400 mm, 2500 mm, 3000 mm, etc.). This cutting must be done without stopping the line, which means the knife’s operation must be fully synchronized with the belt speed.

If the cutting action is not well-timed or the blades are not properly maintained, it can cause:

- Uneven or rough board edges

- Micro-cracks at the cut area

- Misaligned boards in the dryer

- Increased dust and waste

Key Components and Features

- Cutting blade (knife): The core element of the machine. Blade material, sharpness, and edge geometry directly impact the smoothness and quality of the cut.

- Drive system: Ensures that the knife’s movement is perfectly matched with the line speed, allowing for clean, straight cuts without damaging the still-soft core.

- Blade carriage mechanism: Depending on the design, the knife can be a rotating, guillotine, or flying-type system that moves in coordination with the board during cutting.

- Control and automation interface: Integrated into the main line PLC to allow real-time adjustment of cut length, synchronization, and cycle timing.

- Edge support and guiding system: Maintains optimal belt alignment and tension to prevent drift, slippage, or misalignment that could affect board quality

Why Knife Quality and Synchronization Matter?

For Product Quality:

- Clean and smooth edges: High-quality and right design knives ensure the plasterboard has professionally cut edges, essential for easy handling, accurate fitting during installation, and good visual finish.

- Edge strength: Poor cutting can cause edge chipping or microfractures, weakening the board.

- Less dust generation: Proper cutting reduces gypsum dust, keeping the environment cleaner and minimizing cleaning needs.

For Production Line Performance:

- Synchronized cutting avoids jams: If the knife doesn’t match the line speed, it can create irregular cuts, damage the belt, or cause misfeeds into the dryer.

- Minimizes waste and downtime: A precise cutting machine reduces rejections, miscuts, and the need for rework.

- Supports high-speed operation: Modern knife units can keep up with demanding production speeds without sacrificing precision.

The Knife might be a single machine, but its performance has a direct and visible impact on the final quality of every plasterboard. Clean, accurate, and synchronized cutting ensures smooth operation, professional-looking boards, and a reliable flow through the entire line. When paired with the right automation and blade quality, this unit becomes a critical contributor to both efficiency and product excellence.